Séminaire - 08/06/2022 - Kozo FUJIWARA - Fundamental phenomena during solidification process of mc-Si Part 1: Nucleation-growth process

Invitation : Nathalie Mangelinck-Noël (Eq. MCA, Dep. MATER)

Diffusion : IM2NP, CiNaM, Irphe, LP3, Madirel (via P. Boulet), PIIM (via T. Angot), CPT (T. Martin), Fédération de Chimie (via S. Viel)

SEMINAIRE Mercredi 8 juin 2022 à 11h

Salle des séminaires de l'Im2np, campus de Saint-Jérôme, 1er étage Bâtiment Poincaré

Kozo Fujiwara

Institute for Materials Research, Tohoku University

Fundamental phenomena during solidification process of mc-Si

Part 1: Nucleation-growth process

In order to achieve high quality of multi-crystalline Si (mc-Si) ingots for solar cells, it is necessary to control the “grain structure” such as grain size, grain orientation, grain boundaries, dislocations, impurities, etc. During the unidirectional solidification process of mc-Si ingots, various phenomena occur due to the presence of various crystal defects, and these phenomena are extremely complex. Although a fundamental understanding of these phenomena is important for controlling grain structure, the mechanisms by which many of them occur are not yet clearly understood. Therefore, we are conducting in situ experimental studies to clarify what is happening during the solidification process of mc-Si. In this seminar, some of such

phenomena will be described based on our experimental results.

Our in-situ observation system consists of a small crystal growth furnace and an optical digital microscope; the Si raw materials are placed in a silica crucible. The inside of the furnace is evacuated by a rotary pump and then replaced by Ar. Depending on what we want to observe, we control how the raw material is melted and how crystals are grown.

The first part of this seminar will focus on phenomena occurring in the early stages of solidification, i.e., the nucleation-growth process. Crystal growth shapes, growth mechanism of Si dendrite, grain impingements, and the time evolution of the nucleation-growth process will be discussed.

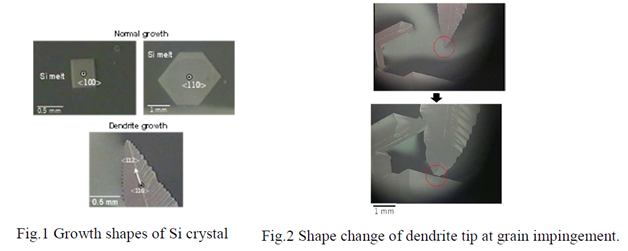

Figure 1 shows the growth shape of Si crystals. In Si, the {111} plane has the slowest growth rate, so normal growth results in crystals with a shape surrounded by {111} planes (top panels of Fig. 1). On the other hand, when there are two parallel twin boundaries in a crystal, the crystal becomes dendrite-like shape (lower panel of Fig. 1).

Figure 2 shows the impingement process between a dendrite crystal and a normal crystal: when the two crystals are far apart, the tip of the dendrite crystal is sharply pointed; when the two crystals are closer, the tip shape becomes flat.