Séminaire - 13/06/2022 - Kozo FUJIWARA - Fundamental phenomena during solidification process of mc-Si Part 2: Directional growth process

Invitation : Nathalie Mangelinck-Noël (Eq. MCA, Dep. MATER)

Diffusion : IM2NP, CiNaM, Irphe, LP3, Madirel (via P. Boulet), PIIM (via T. Angot), CPT (T. Martin), Fédération de Chimie (via S. Viel)

SEMINAIRE Lundi 13 juin 2022 à 11h

Salle des séminaires de l'Im2np, campus de Saint-Jérôme, 1er étage Bâtiment Poincaré

Kozo Fujiwara

Institute for Materials Research, Tohoku University

Fundamental phenomena during solidification process of mc-Si

Part 2: Directional growth process

The control of grain structure is required for the high quality of multi-crystalline Si (mc-Si) ingots for solar cells. In-situ experiments are conducted to clarify various phenomena that occur during the solidification process. The first part of this seminar focused on phenomena occurring during the early stages of solidification. In the second part, we will look at phenomena that occur in the directional solidification process after the nucleation-growth process. The effects of grain boundaries on the change of crystal-melt interface shape, the direction of grain boundary extension, the effect of crystal-melt interface shape on impurity segregation, the formation of small-angle grain boundaries at the crystal-melt interface, and grain

boundary impingements at the crystal-melt interface will be introduced.

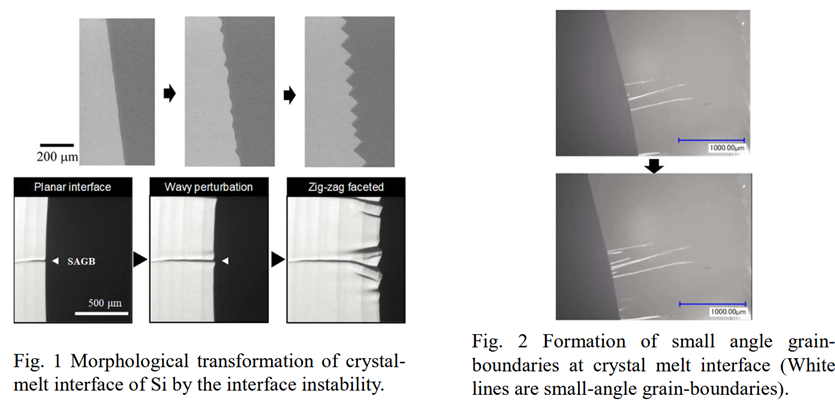

Figure 1 shows the instability of the crystal-melt interface for single crystal (single grain) and crystal containing a grain boundary. In the case of single crystals (upper panels in Fig. 1), as the growth rate increases, the entire flat interface is destabilized simultaneously, forming a zigzag-facetted interface. On the other hand, when a grain boundary is included in a crystal (bottom panels in Fig.1), the instability begins at the grain boundary position at the crystal-melt interface. It was found that the instability begins at a slower growth rate for crystals containing grain boundaries than for single crystals.

Figure 2 shows the formation of small-angle grain boundaries at the moving crystal-melt interface. Etch-pit observations after solidification show that dislocations accumulate with crystal growth and small-angle grain boundaries are formed.

In addition, other phenomena will be discussed based on experimental results.