Séminaire - 22/02/22 - Matias Velazquez - Crystal growth, spectroscopic and mechanical properties of Li2MoO4 bulk single crystals for heat-scintillation bolometers

Invitation : Nathalie Mangelinck-Nöel (Département MATER, Équipe MCA).

Diffusion : IM2NP, CINaM, Irphe, LP3, Madirel (via P. Boulet), PIIM (via T. Angot), CPT (T. Martin), Fédération de Chimie (via S. Viel), CP2M

SEMINAIRE Mardi 22 février 2022 à 11h00

Salle des séminaires de l'Im2np, campus de Saint-Jérôme, 1er étage Bâtiment Poincaré

Matias Velazquez

Univ. Grenoble Alpes, CNRS, Grenoble INP, SIMAP, 38000 Grenoble, France

Crystal growth, spectroscopic and mechanical properties of Li2MoO4 bulk single crystals for heat-scintillation bolometers

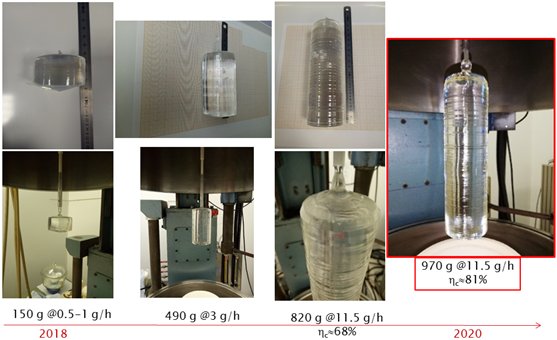

Because of their high resolution and low detection energy thresholds, crucial experiments aimed at understanding the origin of the neutrino mass and at detecting directly dark matter require the detection of extremely rare events, such as neutrinoless double beta decay (2β0ν), by double readout heat-scintillation cryogenic bolometers. In the latter case, these bolometers simultaneously generate a nuclear event and record it in the same crystal that constitutes their core. The most promising crystal to achieve this goal is lithium molybdate Li2MoO4 (LMO). The central part of a Czochralski puller has been designed through numerical simulation in order to optimize the temperature field around the crystal [1]. Initial Li2CO3 and MoO3 powders have been purified by hydrogenocarbonation and by ammoniac route in aqueous solution, respectively. We are now capable of producing routinely kg-mass Li2MoO4 single crystals with 50 mm in diameter, either [110]- or [001]-oriented in the growth direction, at a faster pulling rate (2 mm.h-1) than by the low temperature gradient Czochralski method (LTG-Cz) (Fig. 1). The crystallization mass yield reaches 81% and can still be improved. The crystals do not exhibit any twins, and the dislocation densities are in the range 0.8–1.4 × 104 cm-2 for the crystals 50 mm in diameter. The dislocations in Li2MoO4 are oriented along the [11-20]-direction and contained in the (0001) plane, corresponding to the basal glide system. Crystals with varied diameters were grown in two different Czochralski configurations. The first configuration based on inductive heating (RF coil coupled with Pt crucible) was used to grow crystals of 3 to 4 cm in diameter. We investigated the detector performances and radiopurity of a cracked 158 g crystal and an uncracked 13.5 g crystal. In the latter, a good energy resolution (2–7 keV FWHM @ 0.2–5 MeV), an efficient alpha particles discrimination (10𝜎) and a potentially low internal radioactive contamination (below 0.2–0.3 mBq/kg of U/Th) were obtained [2]. The fractured crystal led to a shorter response time and a second time constant of several hundreds of ms, and a decrease of both the FWHM resolution and the sensitivity by a factor of 17 and 70, respectively. Scintillation spectra at 10 K showed a very broad emission band centered at 558 nm, where ABS-1≈8×r, with r the crystal radius. The T- thermoluminescence contour plots do not exhibit any peak at 58 K, usually assigned to ZnLi°+VLi’ point defects. The crystals exhibit the lowest W and Zn contaminations known to date, which results in one of the highest light yield (0.97 keV/MeV, ~1300 photons/MeV) amongst LMO scintillating bolometers, on the -rays and muons detection bands. This low scintillation light yield is sufficient to establish heat-light discrimination diagrams with discrimination factors (α+t)/() ≈ 9-10. The full tensor of elastic coefficients was measured as a function of temperature by Brillouin spectroscopy, and led to estimates of the bulk and shear moduli of 48 and 18 GPa at room temperature. Hence, Li2MoO4 crystals have a low mechanical hardness which decreases when temperature increases. Besides, when uniaxial compressive tests designed to optimize the Schmid factor for the shear stress –that is, when the compressive stress direction is right between the [0001]- and [11-20]-directions, with a 45° angle from both directions-, the crystals crack without dislocation multiplication and without twin formation, at 450 and 650°C under stresses up to 10 and 7.6 MPa, respectively. With these new inputs, anisotropic stresses occurring during growth have been recalculated by finite element numerical simulation of heat transfer and thermo-elasticity, by means of the same modelling procedure as previously published but applied to the specific set-up configuration used for growing the crystals and with an [001]-oriented seed. The temperature, velocity and stress fields were calculated at three different solidification distances during the growth: at the end of the shoulder, after 3 cm of solidified distance and at the tail of the bulk crystal. The interface deflection is small (3.65 mm measured versus 4 mm calculated), and barely changes with solidification distance, which is an indication of the good thermal stability of the pulling configuration and an indication that the crystallization mass yield can be further improved. The temperature gradient in the crystal reaches a maximum of 30 K.cm-1, which is always located close to the triple phase line. In addition to interface deflection assessments by rapid extraction experiments of the growing crystal at several solidification distances, we measured temperature versus time profiles in selected points of our set-up during the growth of the crystals and also found a good agreement between measured and calculated temperatures. The velocity field in the liquid phase displays only one counterclockwise vortex, the center of which remains in the upper part of the liquid and moves towards the triple point line as solidification proceeds. The velocity decreases as solidification proceeds too, from typically umax=0.015 to 0.011 m/s. All stresses in the xz section of the crystals are now below the minimum crack formation threshold (σmin>3 MPa, σmax<7.5 MPa at 650°C), as determined from uniaxial compressive tests, and they are the strongest at the periphery of the crystal when the shoulder is formed, and in the middle of the solidification interface at further growth stages. The fact that Li2MoO4 exhibits a fragile cracking behaviour without plastic response (either by dislocation multiplication or by twin formation) is a rather uncommon feature for an ionic crystal.